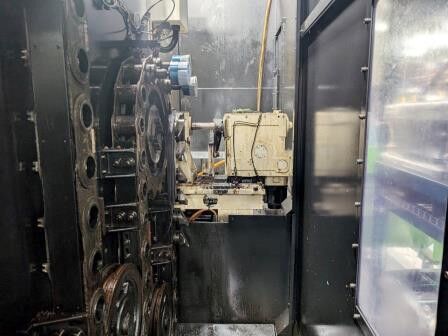

2012 Mazak Integrex i500V w/2 Pallet Changer

Machine Specifications

| Year | 2012 |

|---|---|

| Control Type | Mazatrol Matrix 2 |

| Max Cutting Diameter | 28.74" |

| Travels | X 43.31" Y 31.50" Z 35.43" B 150° C 360° |

| Spindle Speed | 1,000 RPM, 12,000 RPM (Milling) |

| Milling Spindle Speed | 12,000 RPM |

| Equipped With | 2 Pallet Changer, 40 ATC, Capto C6 Connection, Chip Conveyor, Coolant Thru Mil-Spindle System 8kg (115 PSI), Mazak Super Flow T8 High Pressure Coolant 1000 PSI/8 GPM, Overload Detection System, Scale Feedback X,Y,Z, Tool Eye, Work Measuring System RMP 600 |

Request A Quote for this 2012 Mazak Integrex i500V w/2 Pallet Changer Today!

Similar Used Machines

(31" - 50" X-Travel)

2012 Mazak Integrex i500V

The 2012 Mazak Integrex i-200 with 2-pallet changer is a sophisticated multi-tasking machine that merges the functionalities of a robust turning center and a full-featured vertical machining center into a single, compact unit. This VMC boasts a generous maximum swing of 25.91 inches and a machining length of 39.8 inches, making it ideal for processing a diverse range of medium to large complex components. The machine’s powerful 30 HP main spindle, capable of reaching speeds up to 5000 RPM, ensures efficient material removal and superior surface finishes across a variety of materials.

This VMC is equipped with the advanced Mazatrol Matrix control system, offering user-friendly programming and operation to enhance overall productivity. The integrated 2-pallet changer allows for continuous operation, significantly reducing downtime between workpiece changes. Furthermore, the Integrex i-200 features a B-axis milling spindle with a 240-degree travel range, enabling sophisticated 5-axis simultaneous machining for intricate geometries and multi-sided operations.

Key features of the 2012 Mazak Integrex i-200 include:

- 5-axis machining capability with a B-axis travel of 240 degrees

- 36-tool automatic tool changer for extended unattended operation

- Dual-pallet system for increased productivity and reduced setup times

- Maximum bar work capacity of 2.56 inches

- Advanced Mazatrol Matrix control system for efficient programming and operation

The Mazak Integrex i-200 stands out as a versatile and powerful solution for manufacturers looking to streamline their machining processes. Its ability to perform multiple operations in a single setup, combined with the efficiency of the dual-pallet system, makes it an excellent choice for various industries requiring complex part production. To explore how this multi-tasking VMC can enhance your operations or to discuss pricing and availability, we encourage you to reach out to our Used Machinery Staff via email or phone. Our team is prepared to assist you in making an informed decision that aligns with your specific production requirements.