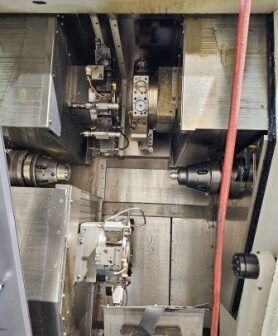

2005 Nakamura Tome Super NTY3

Machine Specifications

| Year | 2005 |

|---|---|

| Control Type | Fanuc 31iA |

| Max Cutting Diameter | 6.9" |

| Machining Length | 23" |

| Max Bar Size | 1.7" |

| Spindle Speed | 6,000 RPM |

| Chuck | 6" |

| Equipped With | 12 ATC, Chip Conveyor, High Pressure Coolant, IEMCA Bar Feeder |

Request A Quote for this 2005 Nakamura Tome Super NTY3 Today!

Similar Used Machines

(6" - 8" Chuck)

2005 Nakamura Tome Super NTY3

The 2005 Nakamura Tome Super NTY3 is a high-performance multi-tasking turning center designed for precision and productivity in demanding manufacturing environments. Equipped with the advanced Fanuc 31iA control system, this machine offers exceptional accuracy and ease of use for complex machining operations. The Super NTY3 features a generous maximum cutting diameter of 6.9″ and a machining length of 23″, allowing for the production of a wide range of part sizes and geometries.

At the heart of this machine are powerful spindles capable of speeds up to 6000 RPM, ensuring high-speed cutting and excellent surface finishes across various materials. The Super NTY3 is equipped with 6″ chucks and can accommodate bar stock up to 1.7″ in diameter, making it suitable for both bar-fed and chuck work. Its robust construction and advanced features make it ideal for industries such as aerospace, automotive, and general manufacturing.

Key features of the 2005 Nakamura Tome Super NTY3 include:

- Fanuc 31iA control system for advanced programming and operation

- Maximum cutting diameter of 6.9″ for versatile part production

- Generous machining length of 23″ to accommodate longer workpieces

- High-speed 6000 RPM spindles for efficient machining

- 12-station Automatic Tool Changer (ATC) for reduced setup times

- Integrated IEMCA bar feeder for continuous material feeding

The Super NTY3 is further enhanced with a high-pressure coolant system, ensuring optimal chip evacuation and tool life, especially during demanding cutting operations. The inclusion of a chip conveyor streamlines the machining process by efficiently removing chips from the work area. Whether tackling complex aerospace components or high-volume automotive parts, the 2005 Nakamura Tome Super NTY3 delivers the performance, flexibility, and reliability needed in today’s competitive manufacturing landscape.